Cincinnati Milacron built large industrial robots primarily for welding industry. It was one of the first companies to change from hydraulic to electric robots. Milacron pioneered the first computerized numerical control (CNC) robot with improved wrists and the tool centre point (TCP) concepts. The first hydraulic machine, the introduced in 1978. It closely resembled the General Electric Man-mate, ITT arm, and other predecessors (Sullivan 1971). Constructed of cast aluminium, it is available in two models of 6-axes revolute jointed arms. The largest, the T3-776, uses ballscrew electric drives to power the shoulder and elbow pitch. The ballscrews replaced the hydraulic cylinders originally used on the T3 robots. The elbow is a classical example of intermediate drive elbow. The same techniques, only upside down, appear in the shoulder. Shoulder yaw is provided by the standard bullgear on a base mounted motor drive. End users have discovered that ballscrews are not sufficiently reliable and are pressuring for an alternators. The eventual disappearance of ballscrews in industrial robots seems inevitable.

CONTROL SYSTEM

The T3 robotic arms is controlled using a Hierarchical Control System.A Hierarchical control system is partitioned vertically into levels of control. The basic comand and control structure is a tree, configured such that each computational module has a single superior, and one or more subordinate modules. The top module is where the highest level decisions are made and the longest planning horizon exists. Goals and plans generated at this highest level are transmitted as commands to the next lower level where they are decomposed into sequences of subgoals. These subgoals are in turn transmitted to the next lower control decision level as sequences of less complex but more frequent commands. In general,the decisions and corresponding decompositions at each level take into account: (a) conrmands from the level above, (b) processed sensory feedback information appropriate to that control decision level, and (c) status reports from decision control modules at the next lower control level.

The figure shown above depicts the schematic block diagram of the integrated control structure as configured on the Cincinnati Milacron T3 Robot. The system is configured in the hierarchical manner and includes five major subsystems:

(1) The Real-Time Control System (RCS)

(2) The commercial. T3 Robot equipment

( 3 ) the End-Effector System

(4) The Vision System

(5) The Watchdog Safety System

The Real-Time Control System as shown in figure is composed of four levels:

(1) The Task Level

(2)The Elemental-Move Level

(3) The Primitive Level

(4)The T3 Level.

The Task, Elemental-Move and Primitive levels of the controller are considered to be Generic Control Levels. That is, these levels would remain essentially the same regardless of the particular robot (commercial or otherwise) being used. The T3 Level, however ,uses information and parameters particular to the T3 Robot and is, therefore, unique to the T3 Robot. The Joystick shown provides an alternate source of commands to the Primitive Level for manual control of the robot and is not used in conjunction with the higher control levels .The T3 Controller shown in figure is part of the T3 Robot equipment as purchased from Cincinnati Milacron. This controller is subordinate to the T3 Level of the RCS and communicates through a special interface.

The End-Effector System consists of a two fingered gripper equipped with position and force sensing .The gripper is pneumatically actuated and servo controlled by a controller which is subordinate to the Primitive Level of the RCS. There are three sensory systems on the robot:

1. The finger force and position sensors on the gripper which report data to the End Effector Controller

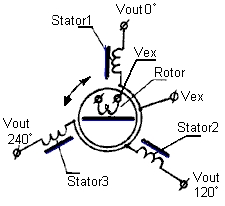

2. The 3 point Angle Acquisition System which reports data to the T3 Controller, the T3 Level of the RCS and to the Watchdog Safety System

3. The Vision System which reports data to the Elemental-Move Level of the RCS.

4. Of the sensor systems, the vision system is obviously the most complex. It performs

sophisticated image processing which requires substantial computational time.

The Watchdog Safety System does not fit directly into the hierarchical control structure. It is an independent system which monitors robot motions and compares them to previously defined limits in position, velocity and acceleration. The Watchdog System has the power to stop the robot if any limits are exceeded and consequently monitors both the mechanical and control systems of the robot.

PARTS OF THE REAL TIME CONTROL SYSTEM

(1)Task Level

The Task Level interfaces with the Workstation Level above it and the Elemental-Move Level below it. In the current configuration, the Task Level has no direct interfaces with sensory systems. The Task Level receives commands from the Workstation Level in terms of objects to be handled and named places in the workstation.

For example, the task might be to find a certain part on the tray at the load/unload station, pick it up and put it in the fixture on the machine tool. This task could be issued as one command from the Workstation Level to the Task Level of the RCS.

(2)Elemental-Move Level

The E-Move Level interfaces with the Task Level above it and the Primitive Level below it. In addition, the E-Move Level interfaces with the Vision System from which it acquires part position and orientation data. The E-Move Level receives commands from the Task Level which are elemental segments of the Task Level command under execution. These are generally single moves from one named location to another. If a part acquisition is involved, data from the Vision System is requested to determine the exact location of the next goal point. The E-Move Level then develops a trajectory between the new goal point and its current position. A trajectory maybe simply a straight line move to the goal point or a more complex move, involving departure, intermediate and approach trajectories. These trajectories can be constructed using pre-stored trajectory segments or data acquired from the Vision System. If no pre-stored segments are found for the desired move and the use of vision data is not appropriate, then a straight line path to the new goal point is calculated.

(3)Primitive Level

The Primitive Level interfaces with the E-Move Level above it and the T3 Level and End-Effector Controller below it. The Primitive Level is the lowest level in the RCS

which is robot or device independent. Subsystems subordinate to the Primitive Level are considered to be at the device level in the control hierarchy. In this system, these subsystems or devices are the robot and the end-effector. T3 The Level shown in figure is not a true control decision level by itself and could be logically combined with the T3 Controller at the device level. The robot and end-effector are, therefore, at the same control decision level subordinate to the Primitive Level. Additionally, the Primitive Level interfaces with the Joystick. The Joystick is a peripheral device which is used for manual operation of the robot. Using the Joystick, the operator can control robot motion in several coordinate systems (world, tool or individual joint motions). Under Joystick control the human operator assumes the higher level planning and control duties normally handled by the E-Move and Task Levels when the robot is operating automatically. The actual Joystick unit has groups of small joysticks, rotory and rocker switches dedicated to each coordinate system. These are configured such t hat the robot will move basically the way the lever is pushed or the switch turned that the robot will move basically the way the lever is pushed or the switch turned, giving the operator a relatively feel for the motion produced ’The Primitive Level receives commands from the E-Move L e v e l in terms of goal points in Cartesian space.These points differ from those received by the E-Move Level from the Task Level in that they are not named locations and therefore assume no knowledge of the Workstation layout. These points are typically more closely spaced than those at the higher Levels although this is not necessarily the case.

(4) T3 Level

The T3 Level interfaces with the Primitive Level above it and the commercial Cincinnati Milacron T3 Robot Controller below it. In addition there is a sensory interface which supplies the six individual joint angles. The T3 Level is so named because elements of it are peculiar to the T3 Robot. From a control hierarchy point of view the T3 Level does not constitute a logical control decision level but is infact a “gray box” necessary to transform command and feedback formats between the Primitive level and T3 controller.

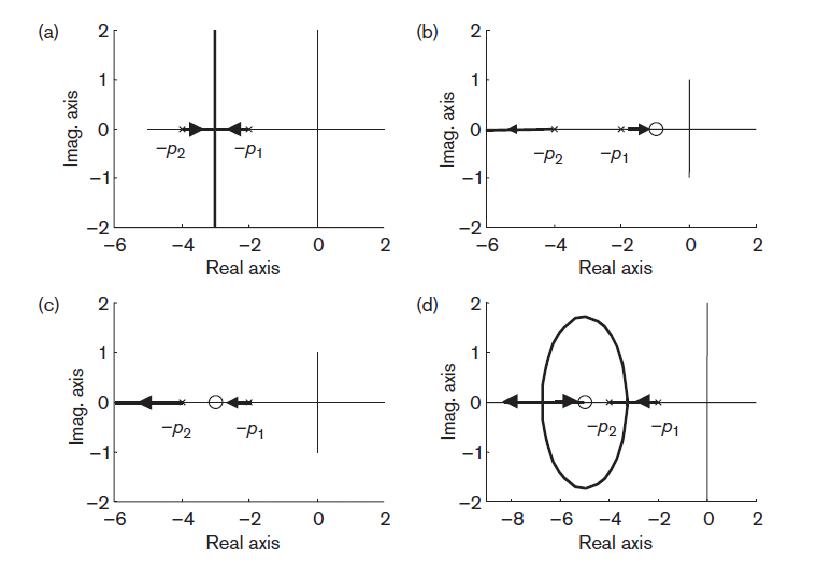

Effect of adding a zero to a second-order system root locus.

Effect of adding a zero to a second-order system root locus.